Automation & Robotics

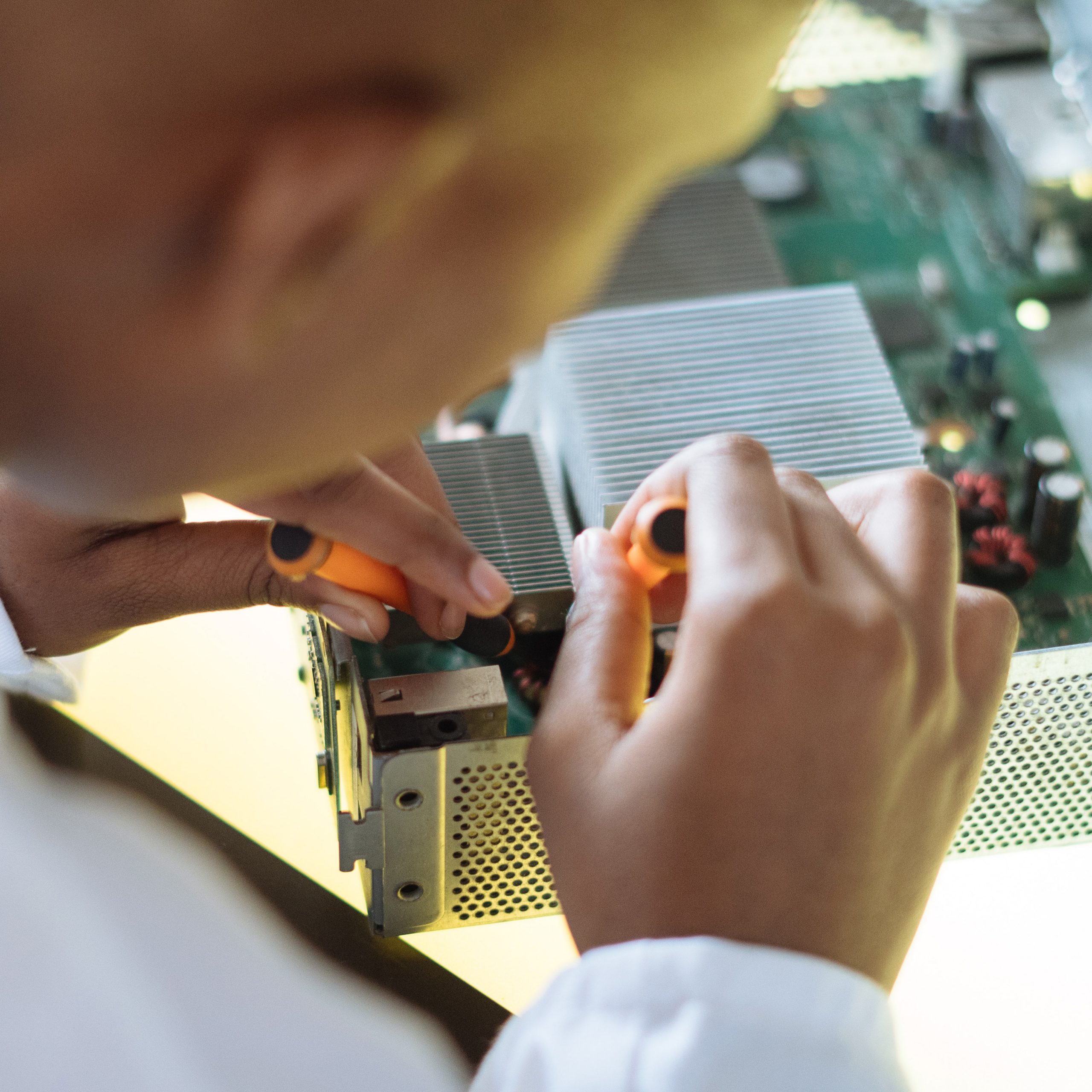

Integro boasts a team of experts encompassing pneumatic, electrical, and mechanical design, software development, machine assembly, wiring, and final testing and validation.

Integro boasts a team of experts encompassing pneumatic, electrical, and mechanical design, software development, machine assembly, wiring, and final testing and validation.

Integro is the IDT division that was established first in 2016, specializing in industrial integration systems, both robotic and non-robotic, primarily within the automotive sector. What sets Integro apart from traditional system integrators is its strong emphasis on the utilization of non-traditional open-source control systems for machinery. Its distinctiveness lies in its ability to conceive and construct fully automated industrial machines from inception to completion.

Elevating Industry with Open-Source Innovation.

We are committed to elevating industry standards through open-source innovation.

Shaping a Future of Technological Excellence.

We aim to shape a future where technological excellence prevails.

Integro’s goal by 2024 is to install Trace and Follow energy and pneumatic monitoring cards in every electrical panel.

OPEN TO THE WORLD

The greatest benefits of open source software are its transparency, flexibility, and cost efficiency. The level of security is usually at least equal to that of proprietary software.

What people usually find difficult to understand is that an open source software is also suitable for professional use in companies and they are not only a makers thing.

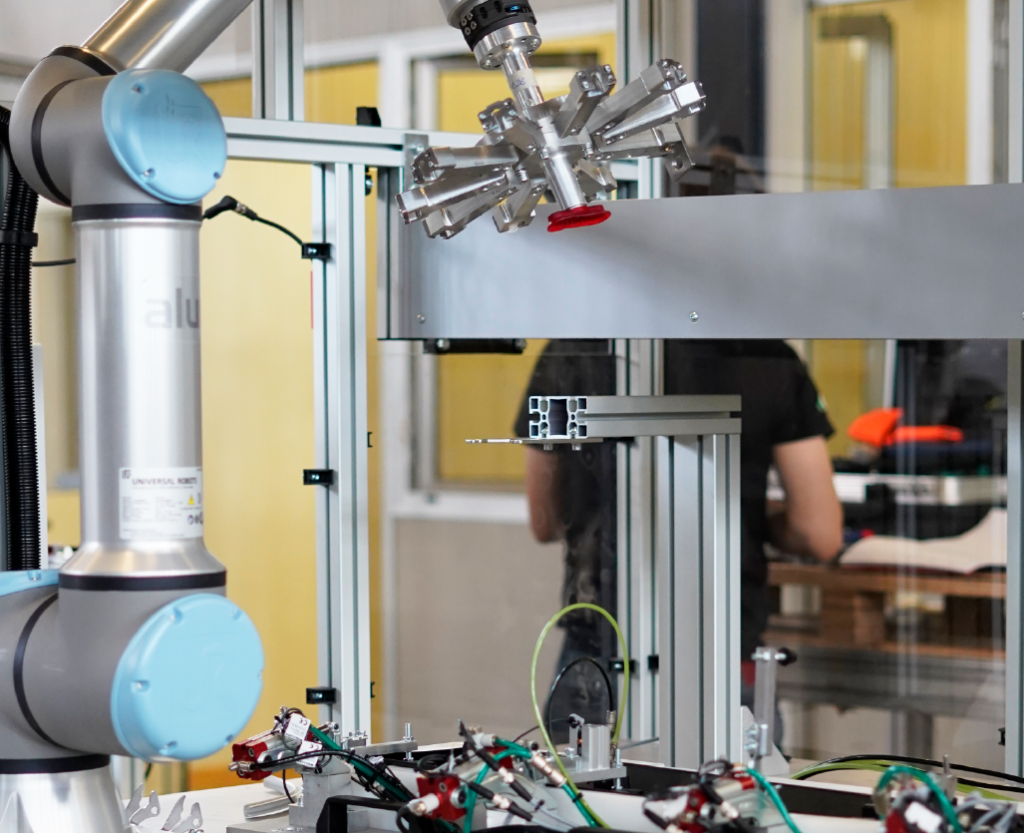

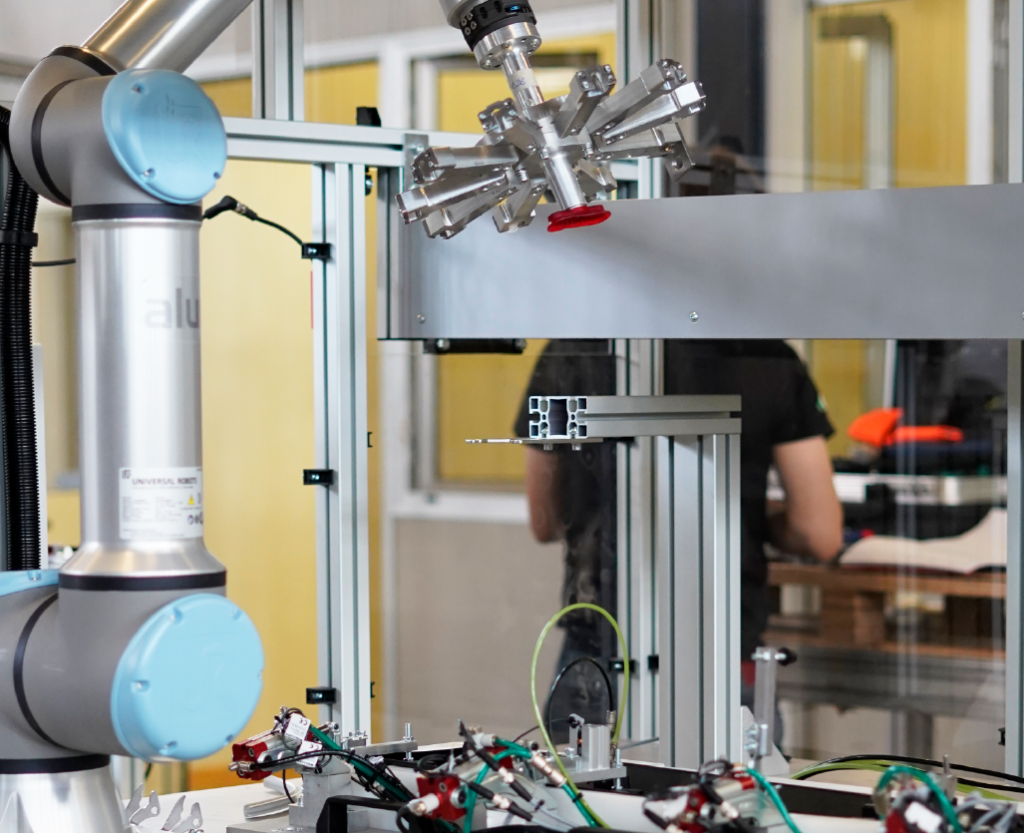

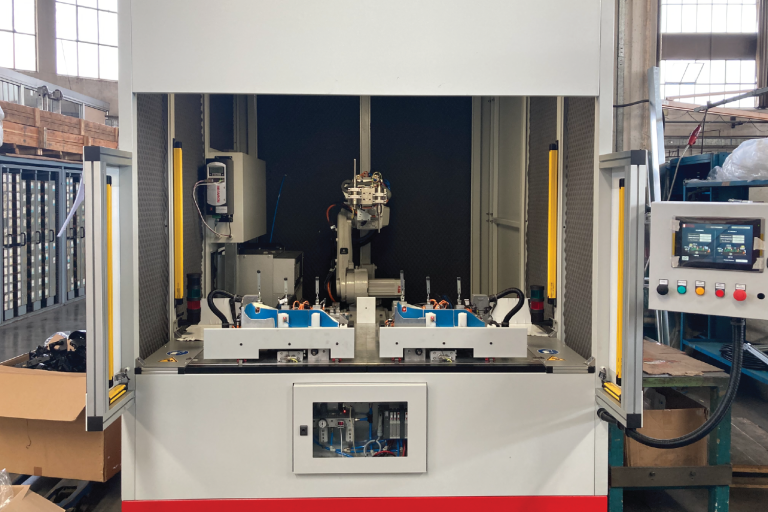

The robotized ultrasonic welder with manual tool change and interchangeable positioning is an advanced technology that combines the precision of ultrasonic welding with the efficiency of robotics, enabling high-quality welds in an automated manner. This device is flexible and suitable for various industries, such as electronics, automotive, and medical device manufacturing, making it essential for modern production lines.

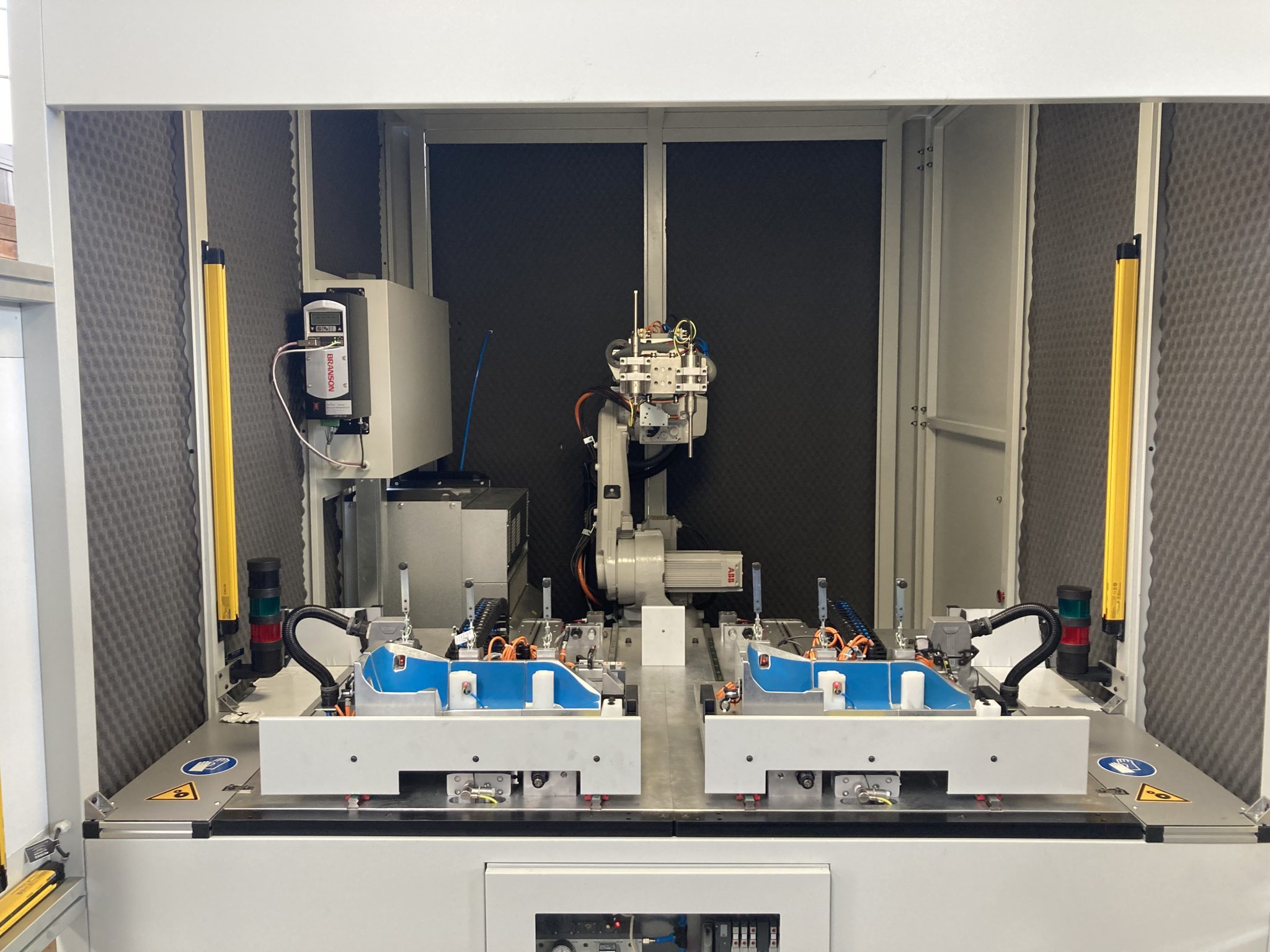

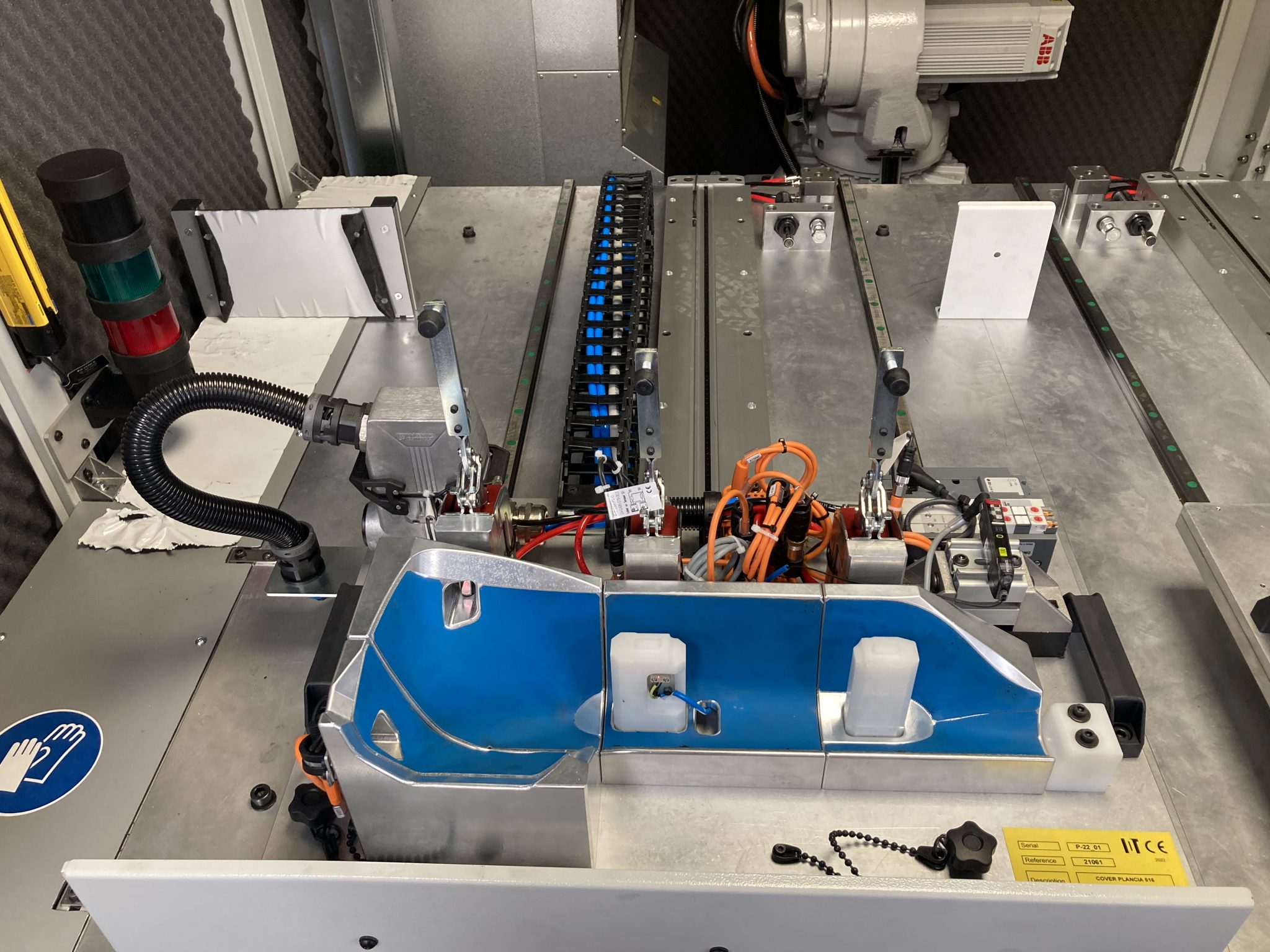

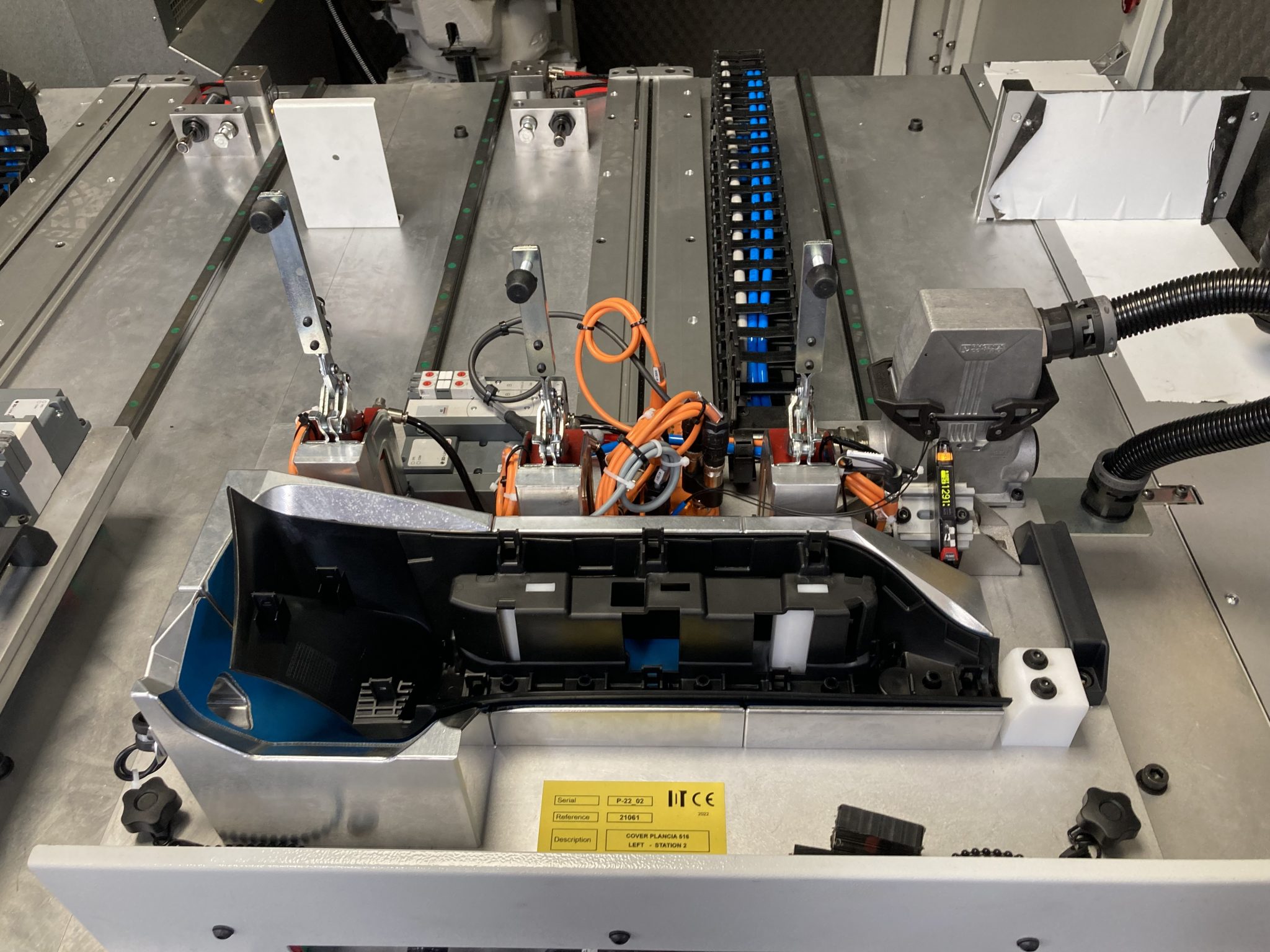

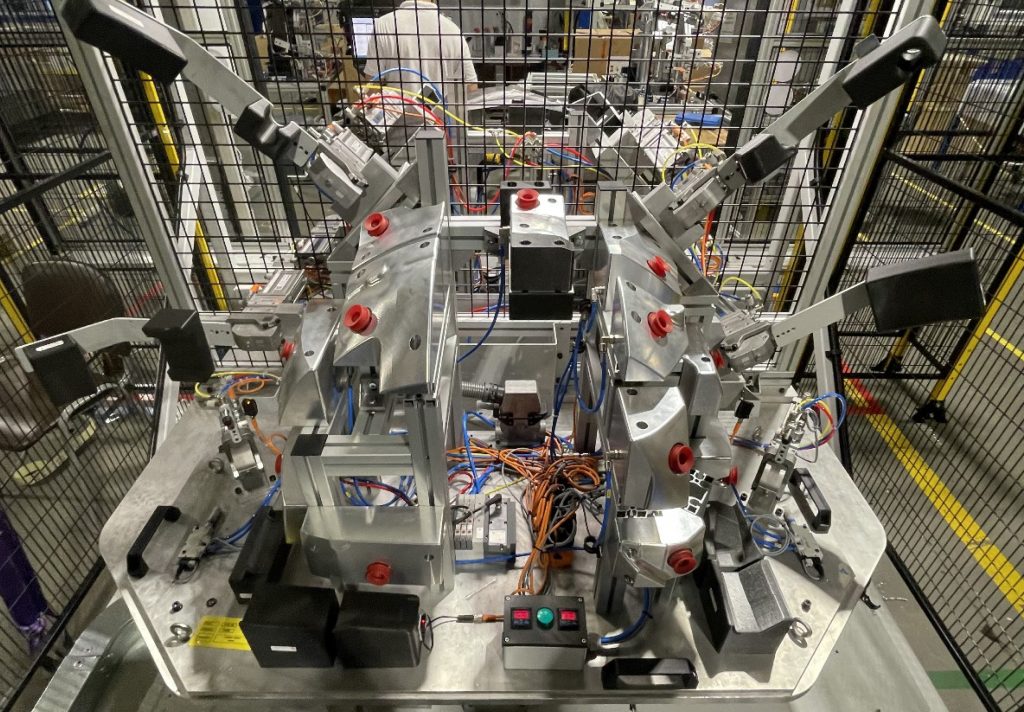

The double-figure robotic welding island offers an advanced solution for the welding process. This cell is equipped with a robot featuring dual sonotrodes, along with two slides capable of accommodating interchangeable fixtures. This configuration significantly enhances welding process efficiency, allowing the robot to work on two pieces simultaneously or quickly adapt to different work setups. This versatile system represents an ideal solution for welding applications that require precision and flexibility.

The robotized ultrasonic welder for large components is an advanced system that combines two robots and a dual-figure rotating table for precise and efficient welding on large-sized pieces. This system is ideal for industries such as aerospace and automotive, providing precision and versatility in large-scale welding processes.

A robotic assembly line for cell integration on electrical testing and contact trimming machines. The operator loads stacks of blister packs containing the cells to be processed. The first robot retrieves them and places them on the testing station, buffering them for the second robot, which then picks them up and places them on the trimming station. Subsequently, the cells are restacked onto carts for the subsequent stations along the production line.

A flexible station for the insertion of metallic and plastic subsidiaries, equipped with interchangeable grippers and vibrators depending on the current production requirements. Once the subsidiaries are inserted, the robot performs a verification using a vision system. At the end of the process, a label is printed for component traceability.

Our sealing verification system consists of two independent stations with manual loading and unloading, designed to test the pneumatic tightness of the three internal chambers of a plastic cup. After the completion of the tests, the system automatically generates a label to ensure full component traceability. This label is subsequently verified by a code reader once applied by the operator.

Some of the services we offer to our clients

Pneumatic, electrical and mechanical design of machines in industrial automation

Wiring and assembly of industrial machines

Industrial software development

Terms of use

A website by Fred Design Studio

@2023 “I.D.T.SRL Società Benefit”All Rights Reserved