CONTACT

HELPFUL LINKS

Terms of use

A website by Fred Design Studio

@2023 “I.D.T.SRL Società Benefit”All Rights Reserved

Trace and Follow lends itself to the Industry 5.0 transition, allowing you to receive up to 45% tax credit. You can monitor energy consumption, raw material usage, and energy efficiency of a single building, department, or machine, whether on mobile or fixed devices!

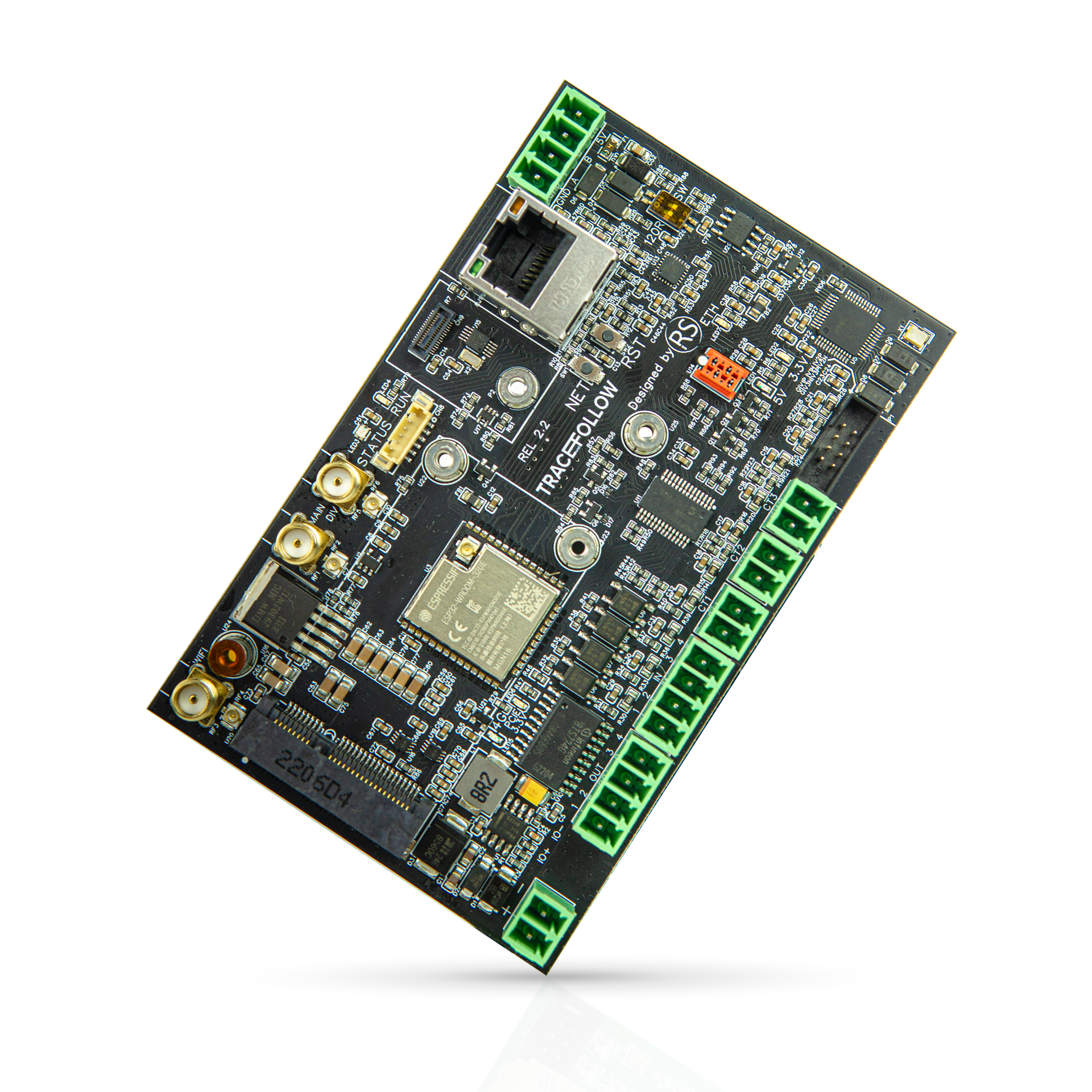

The Trace & Follow Platform is an Integrated Suite of Components capable of monitoring, collecting, systematizing, and processing data from every device on which it is installed. Through its connection, it’s possible to fully map individual machines (manual or automatic), a department, or an entire facility.

The unique feature of the solution is its ability to track production efficiency and associate the collected data with a specific batch or individual product. This production association/monitoring can be achieved by receiving external data from an external system (e.g., ERP) via APIs. Additionally, the platform can remotely control machines (remote shutdown system for energy savings), monitor alarms (maintenance alarms, current threshold alarms, etc.) of the machines, store their data, or geolocate the machine in the facility (through integration with external infrastructure).

Brochures

Documents

The Trace&Follow devices send data to data collection systems on local servers as well as on the Cloud.

It is possible to integrate the data from Trace&Follow devices into your own software or management systems through the use of Open Source APIs.

The data transmission from Trace&Follow devices can occur via WiFi, Ethernet, LTE, or LoraWan, allowing the solution to adapt to any industrial environment.

The uniqueness of the solution lies in its ability, through energy monitoring, to also track production efficiency and associate the collected data with a specific batch or individual product.

In addition to energy monitoring, Trace&Follow devices also collect key data from machines non-invasively through digital I/O, making it a perfect system for machines currently considered obsolete.

Trace&Follow is a platform developed by IDT to monitor energy consumption, raw material usage, and production efficiency for every machine in an industrial plant. It can remotely shut down machines to save energy, monitor alarms, track piece counts, and geolocate machines within the plant.

Transition Plan 5.0 rewards companies with incentives for green transition, allowing them to benefit from a tax credit of up to 45%. By using Trace&Follow to monitor and improve energy and production efficiency, your company can qualify for these incentives.

Trace&Follow offers a wide range of features, including remote monitoring and control of machines, tracking of production efficiency, and associating collected data with specific batches or individual products.

Trace&Follow is compatible with various connectivity options, including WiFi, Ethernet, LTE, and LoRaWAN, enabling reliable connection even in remote areas.

Yes, production monitoring with Trace&Follow can be done by receiving data from an external system, such as an ERP system, through an API interface.

The Trace&Follow board includes four digital inputs, four digital outputs, and a Modbus TCP server to enable command sending and direct data acquisition to and from the machine’s PLC.

No, the product is not tied to a single platform. It can communicate with different platforms through board integration.

Data can be retrieved using dedicated APIs or sent to a third-party platform via MQTT protocol, offering flexibility in data management.

The platform has both a mobile app and a web app for data collection and visualization, communicating with electronic boards through a Cloud infrastructure.

The product’s modular design allows for expansion module installation via RS485 port, offering the possibility to add new functionalities in the future.

Installing Trace&Follow is simple and quick. IDT offers a comprehensive installation and support service.

The cost of Trace&Follow varies depending on the specific needs of the company. Contact IDT for a personalized quote.

Yes, Trace&Follow can be integrated with various existing energy management platforms.

Yes, you can request a demo or a free trial of Trace&Follow to evaluate its features and effectiveness in the context of your business.

Trace&Follow uses advanced security protocols to ensure the protection of sensitive data, including encrypted communications and access controls.

Yes, Trace&Follow can be integrated with machinery from any brand or model, ensuring compatibility with your company’s current machinery fleet.

Machine geolocation is achieved through the integration of an external infrastructure, allowing for the exact location of each machine within the plant.

Trace&Follow offers a comprehensive approach to industrial monitoring, combining energy monitoring, production tracking, and remote control in one integrated platform.

Terms of use

A website by Fred Design Studio

@2023 “I.D.T.SRL Società Benefit”All Rights Reserved